Atoma #140 Diamond Plate with Custom Detachable Handle On

Purchasing as a gift?

What are diamond plates used for?

- Flattening Stones

Diamond plates are often used for flatenning stones. One of the primary reasons why beginners fail in sharpening is using worn and dished stones from usage. A dip that is as thick as hair or even smaller is good enough to slow down your process and result in poor outcomes. How regularly flattening should be done depends on the hardness of stones and how hard and quickly you use. We recommend flattenning the stone every 10 to 20 mins of usage.

- Sharpening Tools

They can also be used as sharpening stones. Many sharpening stones are made of aluminium oxide abrasives and may not cut very hard steels efficiently while diamond abrasives can. The Atoma diamond plates eat so fast, so be cautionous for removing too much of steel. They can also leave deeper scratches than aluminium oxides abrasives for the same grit. What is also good about diamond plates is that they maintain flatness for longer time than stones, so you don't need to flatten them.

Why We Recommend Using the Atoma Diamond Plates for flattening?

The Atoma diamond plates manufactured by Tsuboman Japan are highly regarded due to its slow-wearability, consistancy in abrasive sizes, and fast-cutting performance. Budget flattening stones on the market are made of silicon carbides as opposed to diamond plates like Atoma and can get clogged very quickly during flattening and slow down your flattening process.

Appropriate Size for Flattening?

Inexpensive flattening stones tend to be too small that can leave the sharpening stones dished. The Atoma plate size is very similar to the majority of sharpening stones and large enough to achieve very good flatness.

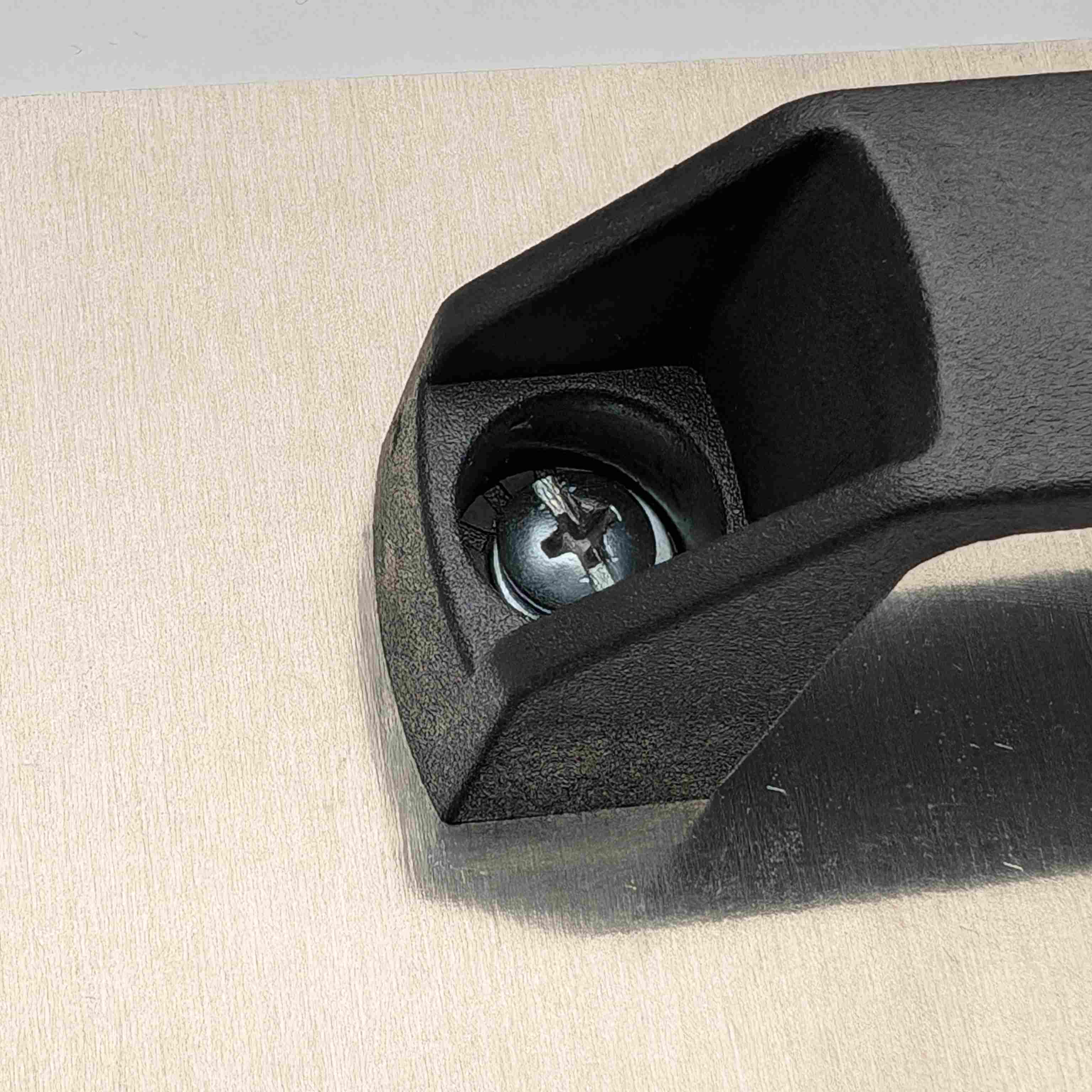

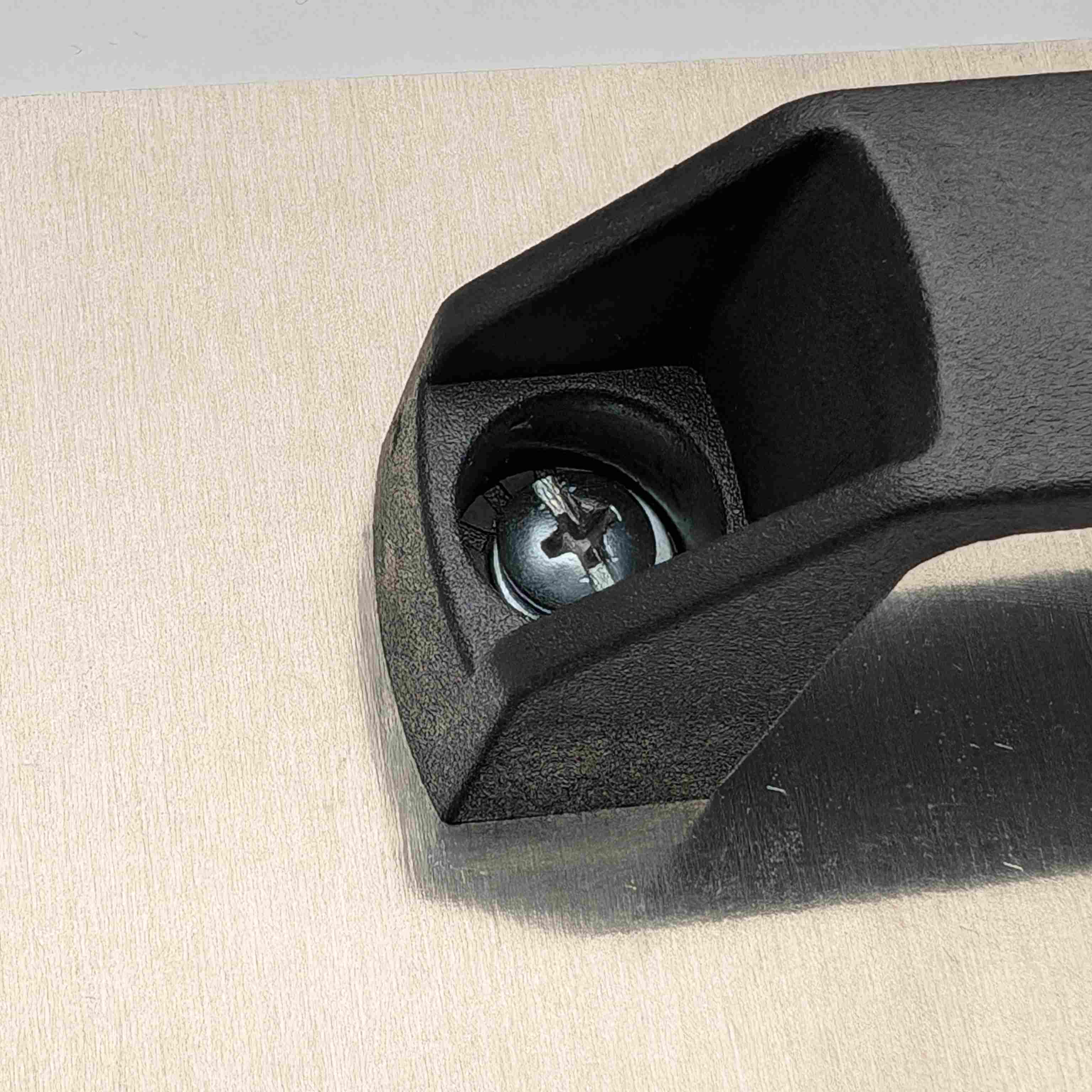

Why The Custom Detachable Handle?

The sharpening stone and the flattening plate often stick very hard together by vacuum effect during flattening. They are both edgy and tricky shapes to hold and won't separate easily even by a strong person. With a handle on the plate, this is not an issue. It also allows an easier and safer operation. Tsuboman produces the plates with fixed handles limiting the usage. When you need a very coarse stone to remove defects like chips and broken tip of your blade, just unscrew the handle and use the Atoma diamond plate as a stone. You can kill two birds with one diamond plate.

Choosing Whestone Grits

- Coarse (~#400)

Use a coarse grit stone/s for fast steel removal, repairing defects such as chips and broken tips, and reshaping the bladeline and geometry. It can also be used to form a cutting edge if the edge was already very blunt, but this will result in a very toothy edge, so we recommend progressing to a medium grit stone at least. - Medium (#600~#2000)

Use a medium grit stone/s for forming a basic and decent cutting edge that is not too toothy or too polished. You will be suprised how sharp it can get just from a medium grit stone if done properly. - Fine (#3000~)

Use a fine grit stone/s for forming a polished edge that enables smooth cuts and reduces damage to food cells.

Specification

- Non-Soaking Type

- Manufacturing Method: Electro-bonding

- Abrasives: Diamond Abrasives

- Stone Size: 210 x 75 x 11 mm

- Stone Weight: 0.7 kg

- Custome detachable handle

- Replaceable diamond sheet is adhered to the aluminium backing plate with double sided tape.

Care and Use

Use

- Saturate the sharpening stone with water

- Rince the plate with water regularly during flattening for the optimum performance.

Storage

- Rince the stone slurry off the plate. Dry before storing.

Choose options

Gift Wrapping and Card

We offer gift wrapping for your purchase. You can also purchase a Hazuki Gift Card to let your recipient choose their own gift.